Materails

What Is Canvas Fabric? A Manufacturer’s Complete Guide

What Is Canvas Fabric? A Manufacturer’s Complete Guide for Sourcing Professionals

For sourcing managers, retailers, designers, and brand buyers: This definitive guide breaks down everything you need to know about canvas fabric for bags—from fiber composition and weave to weight, treatments, and sourcing criteria.

Etymology & Ancient Origins

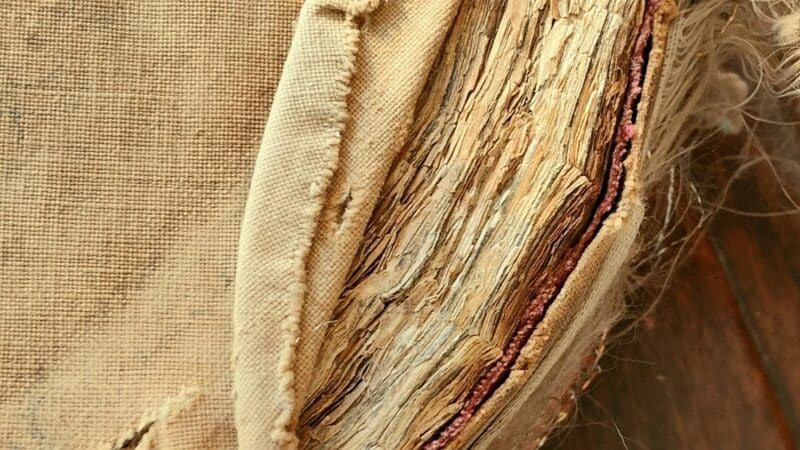

The word “canvas” derives from the Latin “cannapaceus” (made of hemp), via the Greek “κάνναβις” (cannabis). This points directly to its primary original fiber: hemp.

The First Weaves

As early as 1500 BC, civilizations like the Chinese and Mesopotamians wove coarse, sturdy hemp fabrics for shelters and simple bags. Its strength made it ideal for utilitarian purposes long before cotton became the standard.

Canvas History: A Visual Timeline

| Era | Key Development | Primary Fiber | Major Use Case |

|---|---|---|---|

| Antiquity (Pre-8th C.) | Coarse weaving of hemp and flax for shelters, sacks. | Hemp, Flax | Utilitarian cloth, early tents. |

| Age of Sail (8th-19th C.) | Perfected as sailcloth (“duck”); tarred for waterproofing. | Hemp → Cotton | Sails, ship rigging, tarpaulins. |

| Renaissance (15th C.+) | Adoption as a primary support for painting. | Linen (Flax) | Fine Art. |

| Industrial & Military (18th-20th C.) | Mechanized production; standardized for military gear. | Cotton | Tents, packs, uniforms, industrial covers. |

| Modern (Late 20th C.-Present) | Introduction of synthetic fibers; heritage & tech revival. | Cotton, Polyester, Blends | Fashion bags, technical backpacks, lifestyle accessories. |

What is Canvas Fabric? Definition & Core Characteristics

Canvas is a durable, plain-woven fabric historically made from cotton, but now also available in synthetic fibers like polyester. Known for its robustness and versatility, it’s a cornerstone material in bag manufacturing for backpacks, totes, duffels, and more.

Why Canvas Dominates the Bag Industry

Its popularity stems from an unmatched balance of strength, texture, printability, and aesthetic appeal. Canvas offers a “premium utilitarian” look that resonates with consumers, while providing manufacturers with a reliable and workable material.

Types of Canvas Used in Bag Production

Different canvas types serve different purposes in backpack and tote bag manufacturing. Here are the most common options.

1. Cotton Canvas

Natural, breathable, and ideal for lifestyle bags.

2. Polyester Canvas

More water-resistant, colorfast, and cost-effective for mass production.

3. Blended Canvas (Poly-Cotton)

Combines cotton’s aesthetics with polyester’s stabilization and durability.

4. Waxed Canvas

Premium look, water-resistant surface, popular for vintage and outdoor bags.

5. Recycled Canvas (rCanvas)

Eco-friendly option made from recycled cotton or polyester fibers.

Understanding Weight (oz/yd²) & Weave Patterns

Fabric Weight: The Key to Durability

Weight, measured in ounces per square yard (oz/yd²), directly correlates to durability and drape.

- Lightweight (6-10 oz): Good for liner fabric, simple totes, or lightweight packables.

- Mid-weight (10-14 oz): The sweet spot for most backpacks and duffel bags. Balances strength and flexibility.

- Heavyweight (14-18+ oz): Used for heavy-duty tool bags, premium luggage, or structural components. Less flexible but extremely abrasion-resistant.

Weave Patterns: Plain vs. Herringbone

Most canvas uses a tight plain weave. For added visual interest and diagonal strength, a herringbone or twill weave is sometimes used, though it may be less rigid.

Canvas Finishing & Coating Options

Finishing treatments add enhanced performance to canvas used in backpacks and totes.

Popular Finishes

- PU/PVC coating: Adds water resistance and stiffness

- Wax treatment: Creates vintage waterproof look

- DWR coating: Durable water-repellent for outdoor bags

- Soft washing: Provides a softer, casual hand feel

Applications in Backpack & Tote Bag Manufacturing

Canvas is a preferred material in multiple product categories due to its durability, eco-appeal, and premium texture.

Common Uses

- Everyday backpacks

- Fashion totes and shoppers

- Vintage & outdoor bags

- Laptop sleeves and office bags

- Promotional & branded merchandise

Frequently Asked Questions

Is canvas waterproof?

Standard canvas is not waterproof, but it becomes water-resistant after PU coating or waxing.

What weight is best for backpacks?

12-16oz is ideal for producing structured and durable canvas backpacks.

Does canvas shrink?

Cotton canvas may shrink if not pre-washed or pre-shrunk. Manufacturers typically process the fabric to stabilize it.