Materails

What Is REPREVE®? Backpack Manufacturer’s Guide to Sustainable rPET Fabric

What Is REPREVE®? A Complete Guide for Backpack Manufacturers

The Mission: Plastic Waste to Performance Fiber

The core principle behind REPREVE®’s creation was to transform the global issue of plastic waste into a high-performance textile solution, driving the circular economy forward.

- Raw Material Source: The vast majority of REPREVE® fiber is made from 100% recycled materials, most commonly post-consumer PET plastic bottles. For example, a single T-shirt might be made from a few plastic bottles, while a backpack could require dozens.

- Environmental Impact: Compared to producing virgin (new) polyester, manufacturing REPREVE® fiber significantly conserves petroleum, water, and energy. Life Cycle Assessments (LCA) conducted by the manufacturer, Unifi, show a reduction in greenhouse gas emissions ranging from 42% to 77%.

- Performance Features: REPREVE® is not just a sustainable alternative; it matches or exceeds the performance of virgin polyester. It can be engineered with Unifi’s proprietary technologies to offer functional benefits like moisture-wicking (Sorbtek®), odor control (A.M.Y.®), insulation, stretch, and UV protection, making it ideal for high-demand sports and outdoor applications.

The Maker: Unifi, Inc. (A Global Leader in Fiber Technology)

REPREVE® is manufactured and owned by the U.S. company Unifi, Inc., a global leader in fiber science and sustainable synthetic textiles.

- Vertical Integration: Unifi operates a vertically integrated manufacturing process. They control the entire chain, from the collection and processing of plastic bottles into chips, to the final spinning of high-performance fiber and yarn.

- Global Scale: Unifi maintains production facilities in the U.S. (North Carolina), Colombia, El Salvador, and Brazil, ensuring a robust global supply chain to meet the needs of large partners like Nike and The North Face.

- Innovation: Unifi continually expands its waste streams through initiatives like Textile Takeback™, which focuses on recycling textile waste (such as discarded clothing and scrap fabric) back into high-quality circular polyester yarn, supporting a more complete “textile-to-textile” recycling loop.

How is REPREVE® Made? (The Recycling Process)

The journey of REPREVE® fiber is a precise, multi-step process that transforms discarded plastic bottles into high-performance yarn. The process is centralized at Unifi’s state-of-the-art recycling facility in North Carolina, allowing for tight quality control and high-volume output.

1. Collection & Sorting (The Raw Materials)

The process begins with securing the raw material: Post-Consumer PET Plastic Bottles and Textiles Waste.

- Sourcing: Plastic bottles (the same plastic, Polyethylene Terephthalate or PET, used to make virgin polyester) are collected from recycling programs globally. Specialized collections are also made for lines like REPREVE Our Ocean™, sourcing ocean-bound plastic from coastal areas at high risk of marine contamination. Also collection texties waste from Post-Consumer and Post-Industrial Waste Textile Waste and Yarn Waste

- Washing & Sorting: The collected bottles are delivered to the processing center, where they undergo rigorous washing and sorting. Contaminants, labels, and caps must be removed to ensure the resulting fiber is clean and consistent in quality, matching virgin material standards.

2. Shredding to Flakes (Before Transformation)

The materials are thoroughly washed and Sorted, and materials are shredded into small, uniform pieces called flakes. This flake is the foundational ingredient for the new fiber.

3. Melting & Resin Creation (Transformation)

The plastic flakes are melted down and reformulated into a high-quality recycled material known as resin or plastic chips. This step is crucial, as the chemical properties of the recycled PET are optimized to match the performance requirements of new high-quality polyester or nylon resin.

4. Adding FiberPrint™ Tracer (The Traceability Step, key Technologies)

The step that sets REPREVE® apart from generic recycled polyester (rPET) is the addition of Unifi’s proprietary tracer technology.

- Embedding the Tracer: The unique FiberPrint™ tracer is chemically embedded into the recycled resin during the melting or extrusion process. This proprietary ingredient acts as an invisible molecular signature—a “DNA” tag—that is permanently bonded to the fiber.

- Inherent Traceability: Once embedded, the tracer cannot be washed out, diluted, or removed, regardless of how the yarn is dyed, finished, or converted into a final fabric.

- Enabling Verification: This technology is the backbone of Unifi’s U Trust® verification program. It allows third-party auditors to test a finished garment or backpack at any point in the supply chain to definitively prove the material is authentic REPREVE® and confirm the exact recycled content percentage claimed by the brand.

5. Extrusion & Spinning (Yarn)

The resin with FiberPrint™ is melted and extruded (forced through tiny holes, like a showerhead) to form fine filaments, which are then spun into yarn.

Above 5 step REPREVE® have finished their products from Post-Consumer and Post-Industrial Waste in to the high-quality polyester or nylon resin with FiberPrint™ below we will continue introduce the steps how they convert into consumer products.

6. Fabric Creation(Fabric)

Fabric mills purchase the Yarn from UNIFI, INC. And weave the REPREVE® yarn into various fabrics for apparel, home goods, and more.

7. Fabric Creation(Consumer products)

The backpack bags factory or other apparel, home goods, Industrial factory use the fabric with REPREVE® yarn made final procuts like Backpack bags, Cloth, Footwear and other Consumer products

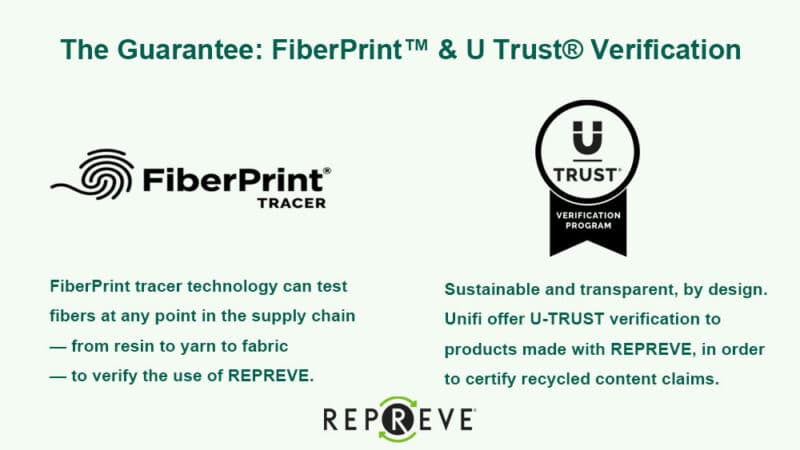

The Guarantee: FiberPrint™ & U Trust® Verification (Key Point for Transparency)

REPREVE®’s most innovative and competitive advantage is its end-to-end transparency and traceability, which directly addresses consumer skepticism regarding recycled content claims.

- FiberPrint™ Technology (The Invisible Tracer):

- During the manufacturing process, Unifi embeds a proprietary, invisible tracer into every strand of REPREVE® fiber. This tracer acts like a unique DNA marker for the fiber.

- This signature cannot be removed or diluted, even after the fiber is spun into yarn, woven into fabric, dyed, and cut into a final garment.

- U Trust® Certification (Verification System):

- U Trust® is Unifi’s third-party certification program.

- Brands and retailers can take a sample of any finished product (e.g., a REPREVE® backpack) at any point in the supply chain. Using specialized equipment, Unifi can quantify and verify the exact percentage of authentic REPREVE® recycled content in the product.

- This provides the highest level of transparency and credibility for partner brands, ensuring their sustainability claims to consumers are certifiable and accurate.

REPREVE® Tag & Label

The REPREVE® Tag & Label program allows brands to showcase their sustainability commitment directly on products.

These tags are widely recognized by consumers and act as a credible proof of recycled content, backed by Unifi’s traceability system.

For sourcing managers and brand buyers, using official REPREVE® labels significantly enhances product transparency, retail value, and marketing impact.

Types of REPREVE® Tags & Labels

- Hang Tags: Attached to backpacks and bags for retail display.

- Bottle counts on hangtags

- Bottle tags on hangtags

- Premium collection tags on hangtags

- Woven Labels: Sewn into internal logos or care labels.

REPREVE Polyester, REPREVE Nylon and Specialty REPREVE® Fibers

While REPREVE® is most famous for its recycled polyester (rPET) derived from plastic bottles, the Unifi brand also includes a recycled nylon fiber, along with specialty options that address specific environmental challenges.

1. REPREVE® Polyester (rPET)

This is the flagship product, focusing on high volume and widespread application.

| Feature | Details | Key Applications |

| Source Material | Post-Consumer PET Plastic Bottles. (The highest volume and most recognizable source.) | Activewear, T-shirts, Fleece, Home Furnishings, Backpacks, Automotive Fabrics, Woven/Knit Fabrics. |

| Material Base | Polyethylene Terephthalate (PET) | |

| Cost & Availability | Generally more cost-effective than recycled nylon due to the high volume of PET bottle waste available globally. | |

| Key Advantage | Highest environmental impact due to diverting massive amounts of plastic from landfills and oceans. |

2. REPREVE® Nylon

This fiber focuses on addressing waste from the textile production side, offering a high-strength alternative to recycled polyester.

| Feature | Details | Key Applications |

| Source Material | Primarily Pre-Consumer Waste (industrial scraps, production overruns, yarn trimmings from manufacturing facilities). | High-end Outerwear, Durable Outer Shells, Swimwear, Hosiery, Luggage, Technical Backpacks (where high tensile strength is critical). |

| Material Base | Polyamide (Nylon) | |

| Cost & Availability | Generally more expensive than recycled polyester due to the higher processing costs and lower availability of clean, pre-consumer nylon waste. | |

| Key Advantage | Superior strength, abrasion resistance, and durability, especially in wet environments. |

3.Specialty REPREVE® Fibers

These innovations target specific consumer needs or unique environmental waste streams.

A. REPREVE Our Ocean™

This is a specific classification of REPREVE® fiber that focuses on ocean-bound plastic waste.

- Mission: This fiber is made from plastic bottles collected from shorelines, waterways, and coastal communities in regions that lack formal waste or recycling infrastructure. The goal is to capture plastic before it has a chance to enter the ocean.

- Application: It carries a powerful storytelling component, making it highly valuable for brands that want to demonstrate a direct impact on marine pollution. It is typically used in consumer apparel and accessories.

B. REPREVE® with CiCLO® Technology

This offering combines REPREVE’s recycled content with an innovative additive to address end-of-life concerns for synthetic fibers.

- What it is: CiCLO® is a textile technology that is incorporated into the REPREVE® polymer.

- Function: It is designed to allow the synthetic polyester and nylon fibers to biodegrade at an accelerated rate when they end up in disposal environments like landfills and seawater, similar to how natural fibers (like cotton or wool) break down.

- Application: Used for garments and accessories where the brand wants to ensure sustainability both at the start of the product life cycle (using recycled content) and at the end (accelerated breakdown).

Key Benefits of REPREVE® for Bags & Backpacks

- Brand Credibility: Trusted by top global brands.

- Consistent Quality: Higher stability compared to generic rPET.

- Traceability: FiberPrint® ensures authenticity.

- Sustainability: Reduces plastic waste and CO₂ emissions.

- High Performance: Durable, abrasion-resistant, and suitable for outdoor bags.

REPREVE® vs Generic rPET: Comparison Table

| Feature | REPREVE® | Generic rPET |

|---|---|---|

| Traceability | ✔ U TRUST® + FiberPrint® system | ✘ Often unverified |

| Quality Stability | High, certified by Unifi® | Varies depending on factory & process |

| Brand Recognition | Global consumer trust | Low |

| MOQ Considerations | Moderate, depending on yarn spec | Lower, more flexible |

| Cost | Higher | More economical |

| Best Use Cases | Premium & sustainable backpack lines | Cost-sensitive mass production |

Which Global Brands Use REPREVE®?

REPREVE® is utilized by brands that have made significant commitments to sustainability, often using the material to replace virgin polyester in their highest-volume collections. These partnerships span apparel, outdoor gear, home goods, and even the automotive sector. Many top consumer brands use REPREVE® for bags, apparel, and accessories. These partnerships have collectively helped divert over 42 billion plastic bottles from landfills and oceans to date

1. Apparel, Sports, & Outdoor Giants

These companies are among the largest consumers of REPREVE® and often feature the material in their performance lines.

| Brand Name | Primary Use of REPREVE® |

| Adidas | Used in many lines, especially for apparel and accessories like backpacks, to support their goal of eliminating virgin polyester. |

| Nike | A major consumer of REPREVE® and other recycled fibers across footwear, apparel, and uniforms. |

| H&M | Recognized by Unifi for recycling more than half a billion bottles; used extensively in their conscious and sustainable collections. |

| Patagonia | One of the earliest adopters of recycled materials, they use REPREVE® and similar recycled fibers in their fleece, jackets, and bags. |

| The North Face | Uses REPREVE® in insulation, fleece, and shells to boost the sustainability profile of their technical outdoor gear. |

| Under Armour | Utilizes REPREVE® for sustainable performance wear and accessories. |

| Quiksilver | Features REPREVE® heavily in their boardshorts, outerwear, and accessories like backpacks, often highlighting the “REPREVE Our Ocean™” fiber. |

| GUESS | Uses REPREVE® across a broad range of products, from denim to dresses and outerwear, as part of their decade-long sustainability initiative. |

This section is critical for demonstrating the massive real-world adoption of REPREVE®. The search results confirm that Unifi (the maker of REPREVE®) works with hundreds of leading brands across multiple industries, having recycled over 42 billion plastic bottles to date.

Here is an organized list of major brand partners, grouped by industry:

Brands That Use REPREVE® Fiber

REPREVE® is utilized by brands that have made significant commitments to sustainability, often using the material to replace virgin polyester in their highest-volume collections. These partnerships span apparel, outdoor gear, home goods, and even the automotive sector.

1. Apparel, Sports, & Outdoor Giants

These companies are among the largest consumers of REPREVE® and often feature the material in their performance lines.

| Brand Name | Primary Use of REPREVE® |

| Adidas | Used in many lines, especially for apparel and accessories like backpacks, to support their goal of eliminating virgin polyester. |

| Nike | A major consumer of REPREVE® and other recycled fibers across footwear, apparel, and uniforms. |

| H&M | Recognized by Unifi for recycling more than half a billion bottles; used extensively in their conscious and sustainable collections. |

| Patagonia | One of the earliest adopters of recycled materials, they use REPREVE® and similar recycled fibers in their fleece, jackets, and bags. |

| The North Face | Uses REPREVE® in insulation, fleece, and shells to boost the sustainability profile of their technical outdoor gear. |

| Under Armour | Utilizes REPREVE® for sustainable performance wear and accessories. |

| Quiksilver | Features REPREVE® heavily in their boardshorts, outerwear, and accessories like backpacks, often highlighting the “REPREVE Our Ocean™” fiber. |

| GUESS | Uses REPREVE® across a broad range of products, from denim to dresses and outerwear, as part of their decade-long sustainability initiative. |

2. Retail, Home Goods, & Automotive

REPREVE®’s versatility extends far beyond clothing, making a difference in everyday items and long-lasting products.

| Industry | Example Brands & Application |

| Retailers | Walmart and Target use REPREVE® in their own brand lines, allowing them to transform billions of bottles into affordable consumer goods. |

| Home Furnishings | Lovesac (furniture) and Precision Textiles (bedding components) use REPREVE® in their products, proving the fiber’s suitability for durable, long-term use. |

| Automotive | REPREVE® is woven into the upholstery of select car models (e.g., Ford F-150 seats), offering a traceable, sustainable option for vehicle interiors. |

This is an excellent addition, as the use of REPREVE® in promotional products and corporate accessories is a huge demonstration of its reach.

I have updated and expanded the “Brands That Use REPREVE® Fiber” section below to include a specific category for bags and accessories popular in the corporate and B2B space, alongside major consumer brands.

Brands That Use REPREVE® Fiber

REPREVE® is the world’s leading recycled performance fiber, and its adoption spans companies committed to sustainability across multiple industries. These partnerships have collectively helped divert over 42 billion plastic bottles from landfills and oceans to date.

1. Apparel, Sports, & Outdoor Giants

These companies are among the largest consumers of REPREVE® and often feature the material in their performance lines, footwear, and consumer bags.

| Brand Name | Primary Use of REPREVE® |

| Adidas, Nike, Under Armour | Used across performance apparel, footwear, and accessories to support goals of eliminating virgin polyester. |

| H&M, Gap Inc., Levi Strauss & Co. | Utilized extensively in apparel collections, including jeans, fleece, and fast-fashion sustainable lines. |

| Patagonia, The North Face, Quiksilver | Features REPREVE® in technical outdoor gear, insulation, shells, and surfwear like boardshorts, often using REPREVE Our Ocean™ fiber. |

| Dagne Dover, Rothy’s | Utilizes REPREVE® in stylish, durable consumer bags (totes, backpacks) and footwear as part of their core commitment to recycled materials. |

2. Retail, Home Goods, & Automotive

REPREVE®’s durability and versatility allow it to be used in long-lasting products far beyond clothing.

| Industry | Example Brands & Application |

| Retailers | Walmart and Target incorporate REPREVE® into their own-brand product lines across various categories, maximizing its impact at scale. |

| Home Furnishings | Lovesac (furniture) and Precision Textiles (bedding components) use REPREVE® for durable, eco-friendly interior fabrics. |

| Automotive | Used in the upholstery of select car models (e.g., Ford F-150 seats), offering a traceable, sustainable option for vehicle interiors. |

3. Corporate & Promotional Gear (B2B)

REPREVE® is widely adopted in the promotional products industry, allowing businesses to replace standard materials with certified recycled content for their corporate giveaways and branded merchandise.

- Tote Bags & Backpacks: Numerous promotional product suppliers (including partners of Unifi like Pinnacle Promotions, Bulletin Bag, and Executive Advertising) offer customizable tote bags, computer totes, and backpacks made from REPREVE® rPET.

- Insulated Coolers: The material’s resilience makes it ideal for insulated tote bags and cooler packs used for corporate events or employee gifts.

This focus allows companies to visibly demonstrate their environmental values. When a company uses a promotional item made with REPREVE®, they are essentially giving their customer a “walking billboard” of their sustainability commitment.

Applications of REPREVE® in Backpack Manufacturing

- School backpacks

- Travel and commuter bags

- Outdoor and hiking packs

- Business and laptop bags

- Fashion backpacks and designer lines

- Sustainable brand collections

Frequently Asked Questions

Q: Is REPREVE® 100% Recycled?

A: REPREVE® fiber is made from 100% recycled materials, primarily post-consumer PET plastic bottles. However, the final fabric is often a blend (e.g., REPREVE® polyester blended with Spandex for stretch) which may lower the overall percentage of recycled content in the garment. Unifi’s technology ensures the portion that is REPREVE® is 100% recycled.

Q: How can I be sure a product with a REPREVE® tag is authentic?

A: REPREVE® is the only eco-performance fiber with U Trust® verification, which uses patented FiberPrint™ technology. This invisible tracer is embedded in the fiber, allowing third-party certifiers to test the final product at any time to verify the exact percentage of REPREVE® recycled content. If you see the official hangtag, the claim has been certified.

Q: Is REPREVE® biodegradable?

A: Like traditional polyester, REPREVE® polyester is not biodegradable and will persist in landfills for a long time. However, it is a significant improvement over virgin polyester because it diverts existing plastic waste from landfills and the ocean. Unifi offers REPREVE® with CiCLO® technology, which is designed to accelerate biodegradation when it eventually reaches a landfill or marine environment.

Q: How does REPREVE® compare in cost to virgin polyester?

A: REPREVE® generally has a higher initial cost than virgin polyester. The premium is due to the added costs of collection, sorting, and cleaning plastic waste, as well as the proprietary technology (FiberPrint™) used for traceability. Brands justify this premium as an investment in a lower environmental footprint and verifiable transparency.

Q: What certifications does REPREVE® hold?

A: REPREVE® holds several key independent certifications, including:

- Global Recycle Standard (GRS): Verifies recycled content and responsible production practices.

- OEKO-TEX® Standard 100: Certifies that the textiles are tested and free from harmful levels of over 100 restricted chemicals.

- SCS Global Service: Provides third-party auditing and verification of recycled content claims.

Q: Is REPREVE® more expensive than normal rPET?

A: Yes, due to its certified traceability and consistent quality. However, brands see strong marketing and sustainability ROI.

Q: Does REPREVE® require higher MOQ?

A: No, the MOQ is the same as other backpack bags fabric.

Q: Can REPREVE® be blended with nylon or spandex?

A: Yes. REPREVE® can be blended for performance or aesthetic needs.

Q: Is REPREVE® washable and durable?

A: REPREVE® behaves like high-quality polyester—strong, abrasion-resistant, and washable..